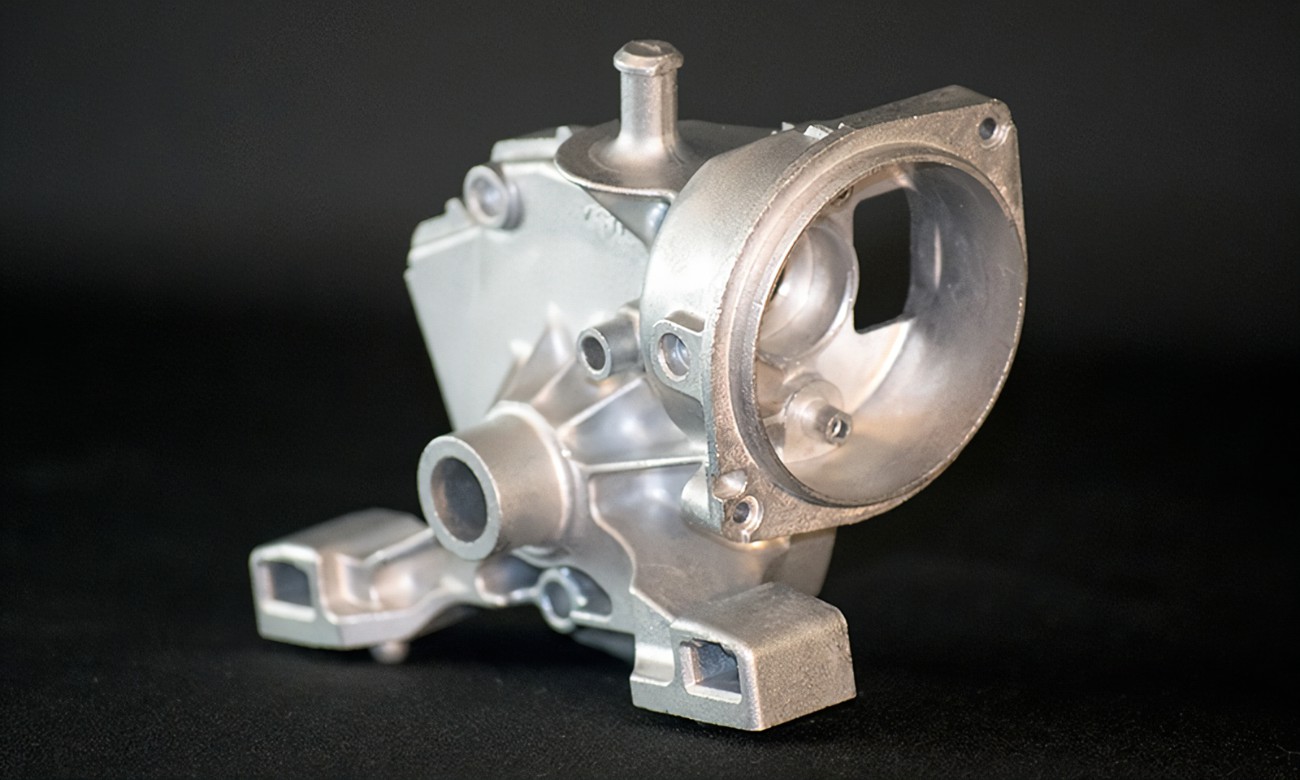

The Die casting technique is a metallurgical technique used since the Victorian period. It produces complex and simple metal parts that have different industrial applications.

Unlike other manufacturing processes, die casting follows a unique approach. It manufactures parts highly functional and enduring in nature. Due to the precision and functional performance of the parts, die-casting is widely used for manufacturing many industrial and consumer products.

Mostly, non-ferrous metals such as zinc and aluminum are used for die-casting. Based on the chemical strengths of these metals, companies die-cast their products.

Automotive Industry

Aluminum is the most widely used metal for die-casting. And, it has applications in the automotive industry as well.

Aluminum die casts replaced iron ones for several reasons. Firstly, it is lighter than iron and provides almost similar strength. Next, it helps manufacture fuel economic parts, which is the main agenda of the automotive industry.

The most common alloy in the automotive industry is Zinc. Firstly, it has the capacity to mold into aesthetic designs while staying durable. Secondly, it offers good anti-corrosive properties.

Electric Industry

The electric industry is the second largest sector utilizing die-casting manufactured parts. Aluminum alloy is again the most common metal here. It is used for its electrical conducting and shielding properties.

Magnesium is the second most common die-casting material. When used in combined die casting it offers good strength and resistance properties.

Aerospace Industry

The aerospace industry also uses magnesium because it has a remarkable lightness and insulating properties. It offers good dimensional stability when molded into net shapes. When fused with a thinner-walled structure the lightness of the product increases significantly which is an important factor in the aerospace industry.

Mining Industry

Mining equipment including drills, heavy-duty excavators, and vehicles use die-cast metallic components. Usually, the alloys used to die cast highly functional mining equipment are steel, grey cast iron, and nickel-chromium.

Custom Jewelry and Decorative

Apart from sturdy and bulky equipment manufacturing, die-casting is also used to prepare delicate decoration pieces and jewelry. The alloy at paly here is tin. Since tin has good fluidity and a low melting point, it is easily molded into decorative shapes.

Furniture

The trends in the furniture industry also changed with the advent of die casting techniques. Aluminum holds a reputation here. Combined with other alloys such as silicon, fine-featured and joint-less furniture pieces are crafted. Moreover, die casting provides the possibility of recycling broken metallic furniture into ideal pieces.

Health Care

Die-casting also has significant applications in the health care industry. Complex machines such as X-ray and ultrasound systems use several die-cast components. Moreover, the hospital beds and the gearboxes attached to them are also examples of die-cast applications. Aluminum alloys A360 and A380 are commonly used to manufacture medical equipment.

Conclusion

Die-casting is an old manufacturing technique that is nowadays used in countless industries. Some of the major industrial applications of die-casting are listed above. However, several other large and small-scale sectors use die-cast components as well.

Manufacturers prefer this method due to low postproduction needs and precision. But, the metal used and the process is chosen solely depends on the function of the product.